UTILIZATION OF DISTILLERY SPENTWASH FOR CROP PRODUCTION

Introduction

Karnataka has 31 primary distilleries with an installed capacity of 300 million litres of rectified spirit. However, the actual production is about 70% of the potential and during 2008-09 it was 206 million litres generating 2400 million litres of spentwash. Though, most of the distilleries utilize part of this effluent for preparation of bio-compost using press mud and applied to agricultural land as a source of nutrients a major portion is still not utilized beneficially. The dosage, time, periodicity and method of application of liquid spentwash for crop production need to be standardized.

Realizing the need for evolving a scientific approach for utilization of distillery spentwash, The Karnataka State Pollution Control Board (KSPCB) advised The Karnataka Brewers and Distillers Association (KBDA) to constitute a Research and Development Advisory Committee (R & D committee) and also provided a seed money of Rs. one lakh, which was supplemented by another Rs. five lakhs in the final year of implementation. In response, the KBDA constituted an R &D committee during January 2003 and entered into a Memorandum of Understanding (MOU) with the two State Agricultural Universities (SAU) in July 2003 to carryout research programmes. The total amount committed for R&D activity for three years was Rs. 86 lakhs, of which Rs. 64 lakhs was for research programmes in the SAUs.

Raw spentwash had low pH of 3.0 to 5.4, high EC of 5.0 to 23.7 dS/M, high BOD of 32,800 to 43,200 mg/l, high COD 76,000 to 108,000 mg/l, and 7.0 to 9.0 per cent TDS. There was a remarkable reduction in BOD, COD and salinity in spentwash after the bio-methanation process but the plant nutrient composition remained the same. Both the raw and primary treated spentwash had 0.1 to o.15% n, 0.8 to 1.2% K2O and appreciable quantities of Ca, Mg, S and micrountrients. On an average, 1m3 of spentwash supplies 1.0 kg N, 0.2kg P2O5 and 10.0 kg K2O, BOD and COD levels remained fairly high (8000 to 17,500 mg/l and 16,000 to 40,000 mg/l respectively) even after primary treatment, making it unsuitable for direct irrigation. Most of the distilleries did not go for secondary treatment.

Characterization of Bio-compost

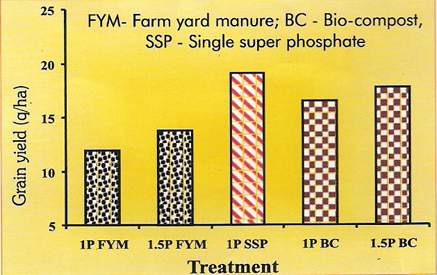

The bio-compst manufactured by the distilleries had ECvalues ranging from 1.10 to 1.42 dS/m (at 1:100 dilution). The organic carbon content ranged between 14.7 and 29.7% with C:N ratio of 11 to 14. The N content varied from 0.8 to 2.0%, P2O5 from 2.4 to 3.9% and K2O from 1.2 to 3.6 % and had higher concentractions of Ca, Mg,S, Fe, Mn, Zn, and Cu. The compost samples did not contain any heavy metals at higher concentrations. From plant nutrient angle, most of the distilleries produced good quality compost.

One time controlled application of treated spentwash to dry lands was taken up on ragi, maize and sunflower by UAS, Bangalore and on maize, sunflower and vegetable crops by UAS, Dharwad. Spentwash was applied to land one month before sowing in kharif season on P requirement basis.

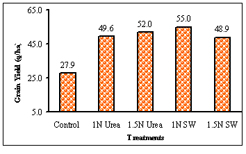

The trials have shown that spentwash at the recommended level of N was better than fertilizer applied at the same dosage. The response of crops to spentwash was higher in the on-station trials compared to on-farm trials indicating the need for scrupulous management in application of spentwash. As the distilleries at present are not charging anything either for spentwash or for transport, there was a net saving of Rs. 1319 to Rs. 2,307 per hectare depending on the crop raised which the farmers otherwise would have spent on fertilizers.

|

|

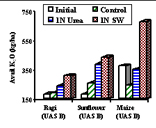

There was significant build-up of K with slight increase in EC, OC, and N content of soil after the harvest of crops indicating that there was no appreciable changes in soil properties within a short span of two years. Interestingly, there was no adverse effect of spentwash application on microbial population of soil. |

| Yield of maize as influenced by different levels and sources of N at UAS, Dharwad | Potassium levels in spentwash applied soils |

The spentwash dosge recommended for different crops was fixed on the basis of N requirement of crops. The required quantity of spentwash equivalent to 40per cent of the recommended level of N was applied at land preparation and mixed into the soil. The remaining 60 per cent of spentwash applied in 3-6 equal split doses before flowering. The crops tested were maize, sunflower, mulberry, sugarcane and vegetables. Mixing of spentwash with irrigation water to dilute it to a level acceptable for irrigation was again as effective as fertilizer application at the same level.

The trends of results remained the same as in case of one time application of treated spentwash to dry land crops. There was slight increase in EC, available K and sulphur content of soil receiving spentwash. No adverse effect was observed on microbial population after three seasons.

irrigation water

The spentwash dosge recommended for different crops was fixed on the basis of N requirement of crops. The required quantity of spentwash equivalent to 40per cent of the recommended level of N was applied at land preparation and mixed into the soil. The remaining 60 per cent of spentwash applied in 3-6 equal split doses before flowering. The crops tested were maize, sunflower, mulberry, sugarcane and vegetables. Mixing of spentwash with irrigation water to dilute it to a level acceptable for irrigation was again as effective as fertilizer application at the same level.

The trends of results remained the same as in case of one time application of treated spentwash to dry land crops. There was slight increase in EC, available K and sulphur content of soil receiving spentwash. No adverse effect was observed on microbial population after three seasons.

Bangalore

Bio-K is spray dried spentwash produced at Ugar Sugar Works, Ugar-Khurd, Belgaum, which contains about 16 per cent K2O. The material was tested on potato by UAS, Bangalore and on sugarcane and wheat by UAS, Dharwad. In both cases, Bio-K gave higher yields compared to same level of K supplied through muriate of potash.

for composting

In decolourization studies at Bangalore, a 42per cent reduction in colour of diluted spentwash (1:1 dilution) was observed due to specific organisms viz., B-3 culture supplied with 0.5per cent glucose as source of energy and peptone (0.3%) as source of protein.

At UAS, Dharwad, microbial consortia YS-8, C-103, YS-4 and UM-3 were found efficient in removing colour up to 58 per cent. Marine fungi isolated from mangroves in Kumta of west coast viz., Ku1, Ku2 and Ku3 deccolourized the 50 per cent diluted spentwash by over 60 per cent within 7 days. Integrated method of decolourization using microbial inoculation followed by chemical treatment (KMnO4) at 5000 ppm resulted in 78 per cent decolourization.

by integrated method

In general, the results of trials on farmers’ fields followed the same trend as in on-station studies at university farms. However, it was experienced that certain infrastructure facilities like storage tanks and application for uniform spreading of spentwash need to be created at farmers’ level. Without a storage tank, adopting ferti-irrigation system was not feasible.

Certain infrastructure facilities like storage tanks and applicators for uniform spreading of spentwash need to be created at farmers’ level. Without a storage tank, adopting ferti-irrigation system was not feasible.

|

| Field day at SLN Distilleries |

|

| Field day at Chamundi Distilleries, Bannur |